NGR Series

HOESCH Standard Size Series –

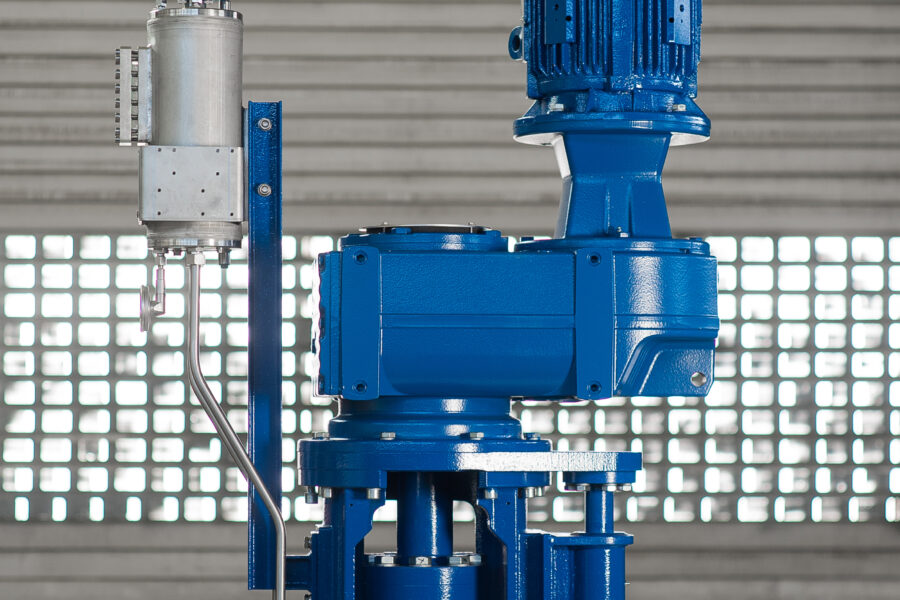

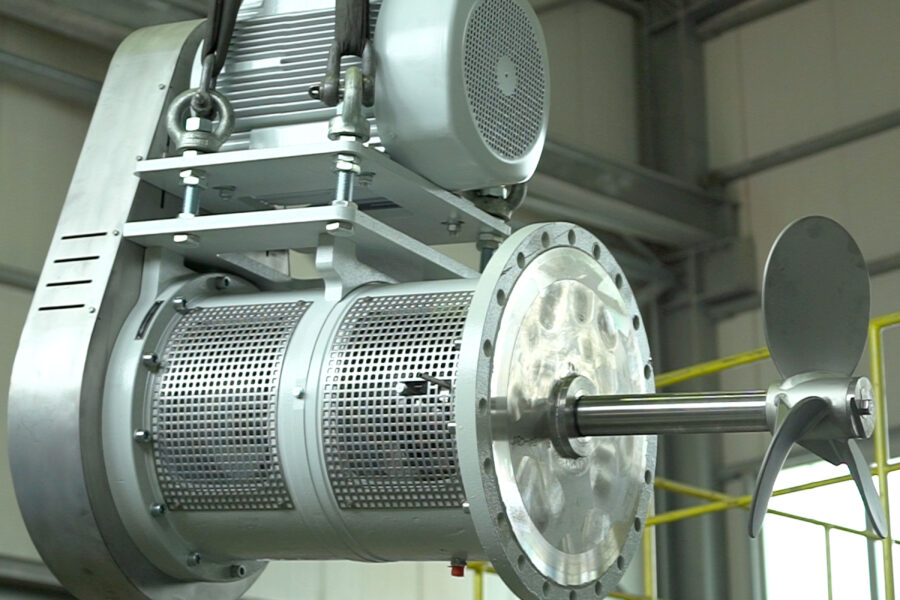

The powerful and robust agitator type NGR

for high system reliability in a modularized design

The powerful NGR series agitators are characterized by their long service life, high availability, low maintenance requirements and low operating costs. The NGR agitator impresses with its wide range of variants and enables customized solutions with short delivery times for a wide variety of applications with medium and high power and torque requirements. Optional installation position from above, from below or from the side in angled installation. The top quality with DIN ISO 9001 and ATEX Directive 2014/34/EU certifications stands for reliability and a long service life.

- One-piece or multi-part agitator lantern made of grey cast iron in modular design (modularized construction)

- Double bearing and flexible coupling

- Shaft diameter 50 mm – 240 mm

- From vacuum to 100 bar operating pressure

- Operating temperature up to 300°C

- ATEX approval

- Options, e.g. cooling flange, speed measurement, shaft catching device, shaft catching ring or shaft foot bearing

Possible shaft seals

- Single or double-acting mechanical seal with supply system or dry-running

- Splash guard, stuffing box, V-ring seal, sealing ring, water cup, lip seals as a cartridge unit

Applications

- Basic chemistry

- Specialty chemicals

- Formulated products

- Biofuels and bioproducts

- Hydrometallurgy

- Storage tanks

- Waste water

- Foodstuffs

- Flue gas desulphurization

Material design of parts in contact with the product

- Carbon steel (ST52-3, C22, ….)

- Coated carbon steel (rubber coating, PP, PE, PVDF, stainless steel cladding, ….)

- Stainless steel (1.4301, 1.4305, 1.4404, 1.4571, ….. )

- Stainless steel for highly corrosive environments ( 1.4439, 1.4539, 1.4529, 1.4565, …. )

- High-performance nickel alloys (Hastelloy C4 ; Hastelloy C276 ; Hastelloy B, Inconell, …. )

- Duplex and superduplex

- Titanium alloys